本公司成立于1998年1月,注冊資金人民幣1280萬元,專業(yè)生產(chǎn)精密不銹鋼無縫鋼管及其相關(guān)產(chǎn)品,冷軋硅鋼、冷軋鋼帶、高頻焊管,公司地屬天下第一村的華西村, 南靠沿江高速公路,北臨長江要塞,水陸交通十分便捷。公司占地面積4.5萬平方米,現(xiàn)有員工200余人,其中專業(yè)管理和技術(shù)人員30余名。

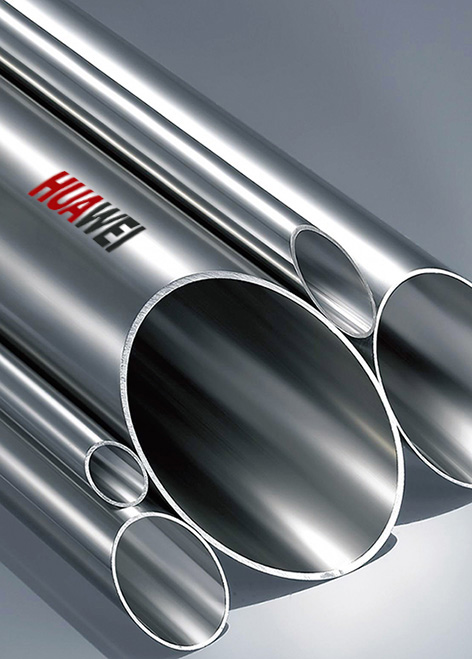

本公司采用先進(jìn)的表面處理技術(shù),確保我們內(nèi)表面拋光等級。 本公司還提供不同的表面拋光的等級來滿足顧客多樣的需求,為顧客節(jié)省成本。 Guaranteed inside diameter surface finish level is attained throughout. A variety of surface finish grades are offered for customer's various application as cost saving options. 我們生產(chǎn)的標(biāo)準(zhǔn)材質(zhì)有:304 ASTM(1.4301 EN/DIN,JIS SUS304);304L ASTM(1.4307 EN/DIN,JIS SUS304L); 316 ASTM(1.4401 EN/DIN,JIS SUS316);316L ASTM(1.4404 EN/DIN,JIS SUS316L)

1

316L SS 超潔凈管,選用特殊的母管,通過控制低的硫含量來提高其焊接的可靠性和一致性。 316L SS UHP tubes&pipes are manufactued from a specially selected mother pipes, controlled lower content of sulfur levels to promote reliable,consistent welding.

2

本公司有無縫、半無縫以及焊接類型,選擇眾多滿足顧客不同的要求,節(jié)約成本。 Seamless,Semi-Seamless and Welded types are available for wide selection and cost saving options

3

BA&EP管通過化學(xué)清洗以及酸洗處理來控制非揮發(fā)性殘留,以此來滿足ASTM G93或者SEMI E49.6要求。 超潔凈管通過高精度清洗(18MΩ 的超純水)后以高純度氮?dú)猓?9.9995%濃度)沖吹凈化管道,并在管內(nèi)充填,最后在10級無塵室包裝。 BA&EP grade tubes&pipes are chemically cleaned and passivated to keep nonvolatile residue levels to comply with ASTM G93 or SEMI E 49.6. UHP tubes &pipes are rinsed with 18MΩ di water and purged with 99.9995% filtered nitrogen and are packed in an class 10 cleanroom.

4

每一根管子都進(jìn)行噴碼,包括制造商、材料類型以及加熱編碼等信息。 BA&EP管通過如下方式包裝:末端和首端裹上PA薄膜,橡膠保護(hù)帽封口后,BA管用單層防靜電袋包裝,EP管用雙層防靜電袋包裝。 Each tube&pipes is marked to identify manufacturer,material type and heat code. BA&EP grade tubes&pipes are packed as following manner:eds are faced and protected with polyamide nylon film and polyethylene caps, packed in single(BA grade) or double(EP grade) polyethylene bags.

5

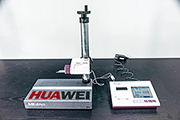

我們有多種專業(yè)的檢驗(yàn)設(shè)備:掃描電子顯微鏡、能譜儀、粗糙度儀、粒子計(jì)數(shù)器、硬度計(jì)、露點(diǎn)儀、金相顯微鏡、拉力試驗(yàn)機(jī)等。 We have a variety of professional inspection equipment:Scanning Electron Microscope(SEM),Energy Dispersive Spectroscopy(EDS), Surface Roughness Gauge,Particle Counter,Micro Vickers,Moisture Analyzer,Metallography Microscope,Tensile Testing Machined etc.

超潔凈管根據(jù)如下P/N進(jìn)行下單 UHP Tubes/Pipes are ordered by part number as shown as right. T-S-12-1.24-4-E-316,代表無縫管,1/2“外徑,1.24壁厚,長度4米,EP,材質(zhì)316。 The following part number,T-S-12-1.24-4-E-316,is designated for seamless Tube,1/2"OD,1.24mm WT,4 meters per length,EP,grade of 316.

無縫、半無縫以及焊接鋼管、以精密的機(jī)器制造工藝,獨(dú)特的技術(shù)以及嚴(yán)格的質(zhì)量管控流程,來確保產(chǎn)品品質(zhì)。 Seamless,Semi-seamless and Welded tubes & pipes are manufacturing throughout state art of equipment, unique technologies and strict quality assurance process.

我們有多種專業(yè)的檢驗(yàn)設(shè)備:掃描電子顯微鏡、能譜儀、粗糙度儀、粒子計(jì)數(shù)器、硬度計(jì)、露點(diǎn)儀、金相顯微鏡、拉力試驗(yàn)機(jī)等。 We have a variety of professional inspection equipment:Scanning Electron Microscope(SEM),Energy Dispersive Spectroscopy(EDS), Surface Roughness Gauge,Particle Counter,Micro Vickers,Moisture Analyzer,Metallography Microscope,Tensile Testing Machined etc.

不同的內(nèi)部表面拋光技術(shù)獲得不同等級的鋼管。請參考我們提供的表面等級、化學(xué)成分表、物理性能、粒子供給實(shí)驗(yàn)及其他品質(zhì)檢驗(yàn)項(xiàng)目及標(biāo)準(zhǔn)、尺寸公差參數(shù)。 Tubes & Pipes are available with different inside diameter finish levels.Please refer to our offer surface grade、Chemical Composition、Physical Prorerties、Particle Contribution Test、Quality Sssurance Values、Dimension Tolerance.